The Impact of Surface Finish Requirements on Manifold Cost and Performance

Key Takeaways

- Importance of texture quality in production processes

- Evaluation and verification of surface quality

- Resolving problems related to surface quality

- Economic assessment of various surface textures

The Role of Surface Finish in Manufacturing

Surface finish may seem like the drab, distant cousin at the manufacturing family reunion, but it plays a critical role in determining a product’s performance. Just think about a hydraulic manifold. Its smoothness can either enhance fluid flow or create enough turbulence to rival a rock concert's bass drop. A polished finish can reduce friction, improve efficiency, and prevent premature wear; conversely, rough finishes can lead to leaks or catastrophic failures. So, a manifold manufacturer who ignores surface requirements might as well serve up a side of spaghetti with their precision engineering — no one wins when everything gets tangled.

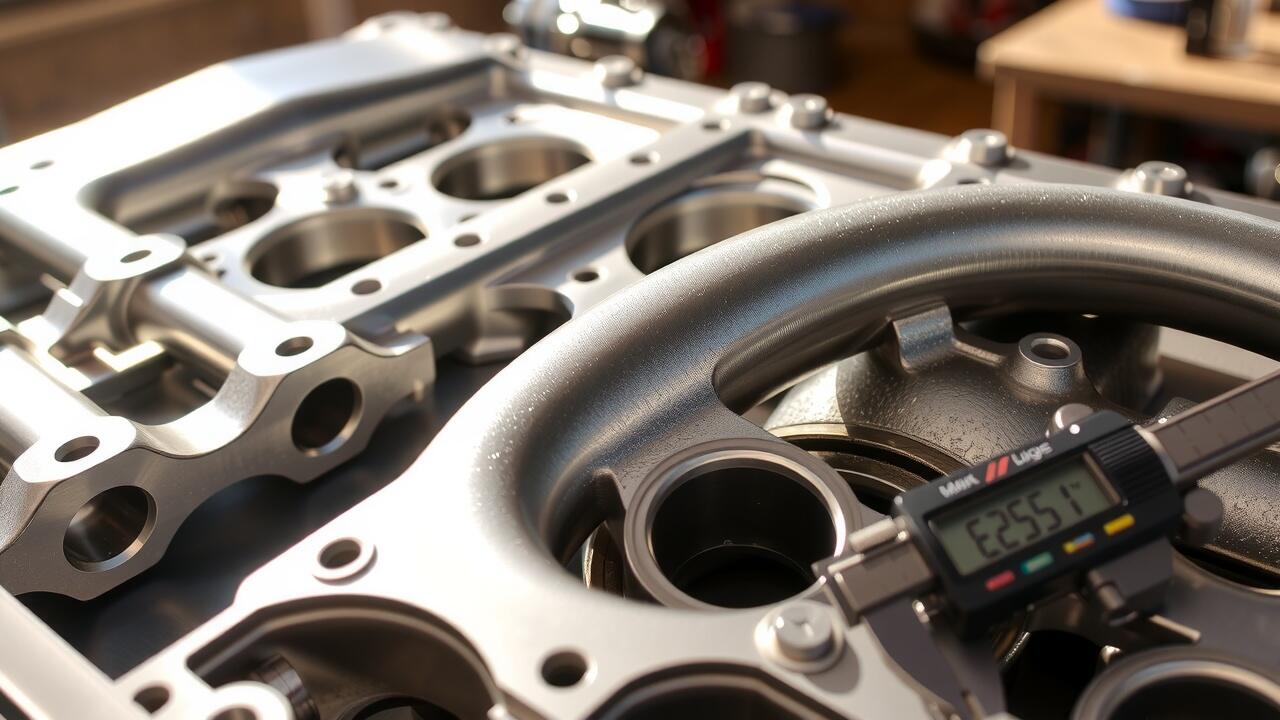

A study by the American Society of Mechanical Engineers indicates that up to 50% of manufacturing defects stem from inadequate surface finishes. Custom manifold manufacturing processes require careful attention to these details. Engineers must consider roughness measurements, such as Ra and Rz values, which quantify the texture. Adhering to industry standards, like ISO 1302 for surface texture, requires no less than meticulous planning and execution. For instance, the use of abrasive blasting prior to machining can vastly enhance the final product's durability while gently massaging that rough exterior into a smoother, more efficient design. Balancing cost with these finish requirements can feel like negotiating a peace treaty, but it's often worth every penny in the long run.

Why Should Manufacturers Pay Attention to Surface Finish?

Surface finish isn’t just the cherry on top of a manifold; it’s the whole sundae—without it, you’re just left with a sad, empty bowl. Poor surface treatment can lead to inefficiencies, leaks, and even catastrophic failure in hydraulic systems. Imagine being a hydraulic manifold manufacturer who skipped the surface finish, only to have your creation start leaking like a teenager sneaking a late-night snack from the fridge. That wouldn't just be a recipe for disaster; it could also lead to hefty warranty claims and reputation damage that takes years to repair.

Attention to detail often separates industry leaders from those who fall behind. A study showed that neglecting surface finish requirements can lead to increased friction, which diminishes performance by 30% or more. In custom manifold manufacturing, precision matters. Non-compliance can also violate industry standards, resulting in costly rework and delays. By prioritizing surface finish, manufacturers not only enhance product reliability but also create stronger customer relationships built on trust and quality.

Surface Finish Testing and Validation

Testing surface finishes can feel like a game of hide and seek. The right equipment helps reveal those paint-thin imperfections that the naked eye might miss, lurking in the shadows like a ninja at a banquet. For manifold manufacturers, ensuring that every surface has a precise texture isn’t just about aesthetics. It’s a crucial part of how the manifold performs. Research shows that a surface roughness increased by just 1 µm can reduce hydraulic efficiency by up to 10% in some applications. Talk about a rough day at the office!

When you dive into validation processes, it’s a lot like prepping for an amusement park visit. You wouldn't hop on the roller coaster without checking the safety bar first, would you? For custom manifold manufacturing, employing techniques like laser scanning and profilometry can pinpoint issues swiftly. Implementing standards from organizations like ISO allows manufacturers to not just meet, but exceed, surface finish requirements. Gathering data and documenting results ensures that repeat performance is not a gamble, but a reliable outcome. So grab that testing gear and remember, a smooth surface leads to smoother operations!

How Can You Ensure Your Surface Finish Meets Requirements?

Ensuring that your surface finish meets requirements can be akin to teaching a cat to fetch—challenging but not impossible. First, invest in high-quality equipment that is the crème de la crème of the manifold manufacturing world. Tools such as laser scanners and profilometers offer precise measurements. With the right instruments, you can capture surface roughness values that would make any meticulous engineer proud. Remember, while you may wish for your surfaces to be smoother than a silk shirt, adhering to industry standards is non-negotiable. ISO 1302 and ASME B46.1 provide excellent guidelines.

Regular audits are your friends here, much like that extra shot of espresso on a Monday morning. These inspections help identify deviations from the desired finish early on. If you're working with a hydraulic manifold manufacturer that insists on cutting corners, you might end up with a manifold that performs about as well as a screen door on a submarine. Implementing corrective actions based on inspection outcomes keeps quality consistent, ensuring that each custom manifold manufacturing process is always a joy rather than a headache.

Troubleshooting Surface Finish Issues

When dealing with surface finish issues, the last thing you want is to channel your inner detective. That’s right, no one signed up for CSI: Manifold Edition, but here we are. For a hydraulic manifold manufacturer, a rough surface can be as unwelcome as finding a fly in your soup. A case in point: a custom manifold manufacturing operation discovered that inconsistent grinding techniques led to increased wear and tear on seals—resulting in replacements coming in at 30% more frequent than expected. Who knew the path to hydraulic smooth sailing could become a bumpy ride?

Now, let’s talk solutions—but without the need for a magnifying glass or a spirit of ghost hunting. One approach is to establish a robust inspection protocol. Picture this: setting up a laser scanning station that can measure surface roughness to 0.1 micrometers; sounds fancy, right? This little number ensures your surface meets those rigorous industry standards. By employing statistical process control (SPC) techniques, manufacturers can pinpoint fluctuations in surface quality and react before a batch ends up looking more like modern art than a finely tuned component. Identifying and addressing these surface finish issues proactively not only saves money but also elevates performance—meaning every manifold can shine, literally and figuratively.

3 Common Problems and Their Solutions

Surface finish issues can be as pesky as a mosquito at a picnic. One prevalent problem for manifold manufacturers is surface roughness that exceeds tolerances. Imagine a hydraulic manifold manufacturer trying to assemble a fitting only to discover it resembles a mountain range rather than a sleek surface. This scenario can lead to leaks or performance issues, which, let's be honest, isn't a great look for any custom manifold manufacturing operation. The solution? Utilize advanced surface measurement tools, like laser profilometers, to get an accurate read on those surface specs before production hits full swing.

Another amusing blunder involves improper surface treatments, which can turn a top-tier product into a fancy paperweight. A manifold with uneven coating can suffer from corrosion or wear, ultimately driving up costs. For example, a recent case involving an automotive manifold manufacturing firm showed that switching to a more reliable surface finish specification reduced warranty claims by 25%. Implementing rigorous quality control measures during the surface treatment process, including adherence to ISO standards, can help nip these issues in the bud. Always remember: a smooth manifold is a happy manifold!

- Always double-check your surface measurements; even a smidgen of roughness can cause a massive headache later on.

- Consider investing in training for your team—after all, even the brightest minds can struggle with the right coating technique!

- Turn surface finish reviews into your team's scavenger hunt; the more precise they are, the fewer leaks you'll encounter.

- Use coatings that don’t just look good but can withstand a little wear and tear; because who has the budget for frivolous re-manufacturing?

- Keep a sense of humor during quality control—laughter is the best lubricant for when things get sticky!

- Always allow for a trial run with your surface treatments; it's easier to fix a minor mishap than to deal with a full-blown catastrophe down the line.

- Remember, a little attention to detail now could save you from crying over spilled hydraulic fluid later!

Cost-Benefit Analysis of Different Surface Finishes

When comparing surface finishes, it’s like choosing between a sports car and a sensible sedan. Each has its unique perks, but only one will make your manifold manufacturing line race ahead of the competition. A smooth finish may be the equivalent of a smooth ride, significantly reducing friction and wear within hydraulic systems. This can lead to a staggering increase in performance, with some manufacturers reporting up to a 30% improvement in efficiency. On the other hand, a rough finish might save costs upfront but could lead to costly repairs and machine downtime later.

Every manifold manufacturer faces the daunting decision of prioritizing cost versus quality. Consider a case where a company saved $2,000 by opting for a rougher finish; their machines experienced a 15% increase in failure rates just three months later. Sometimes, penny-pinching leads to dollar-shedding. The true cost of a surface finish can be evaluated not just in dollars, but in operational efficiency and longevity. Custom manifold manufacturing might require a higher initial investment, yet the returns can be multiplied as the lifespan of the component increases. A polished finish is not just an aesthetic choice; it’s a performance enhancer that can make regular maintenance feel like a luxurious spa day.

FAQS

What’s the big deal about surface finish in manufacturing?

Think of surface finish like the icing on a cake. Without it, your manifold might look tempting, but it could be a rough ride! A good finish ensures everything runs smoothly and keeps your performance sweet.

Can I just ignore surface finish requirements and save some cash?

Sure, if you'd like to turn your manifold into a costly paperweight! Ignoring surface finish may save a few bucks now, but it could lead to a whole lot of headaches later—trust me, that’s one bill you don’t want to foot!

How do I know if my surface finish is up to snuff?

You could always throw a party and invite your manifold for a “finish check.” But seriously, it’s best to rely on proper testing methods and validation processes to ensure your finish meets the requirements—no party hats needed!

What are some common surface finish issues, and can they be fixed?

Absolutely! Think of it like fixing your hair after a windy day. You might deal with rough patches, inconsistent textures, or unwanted burrs. Just remember, with the right troubleshooting tools and methods, you can tame that messy mane back into shape!

Is there really a cost-benefit analysis for different surface finishes?

Oh, you bet! It’s like comparing the price of a fancy latte to your everyday cup of joe. You might pay more upfront for a slick surface finish, but the performance boost and longevity can make it worth every penny—plus, who doesn’t love a good upgrade?